Key features and benefits

- maximized magnetic fields

- higher magnetic field with less energy (minimized energy requirement)

- higher productivity

- optimized stress distribution

- optimized magnetic profile

- application specific safety enclosures

- application specific cooling

- FEM supported fixture design & simulation

- end user's production requirements

About

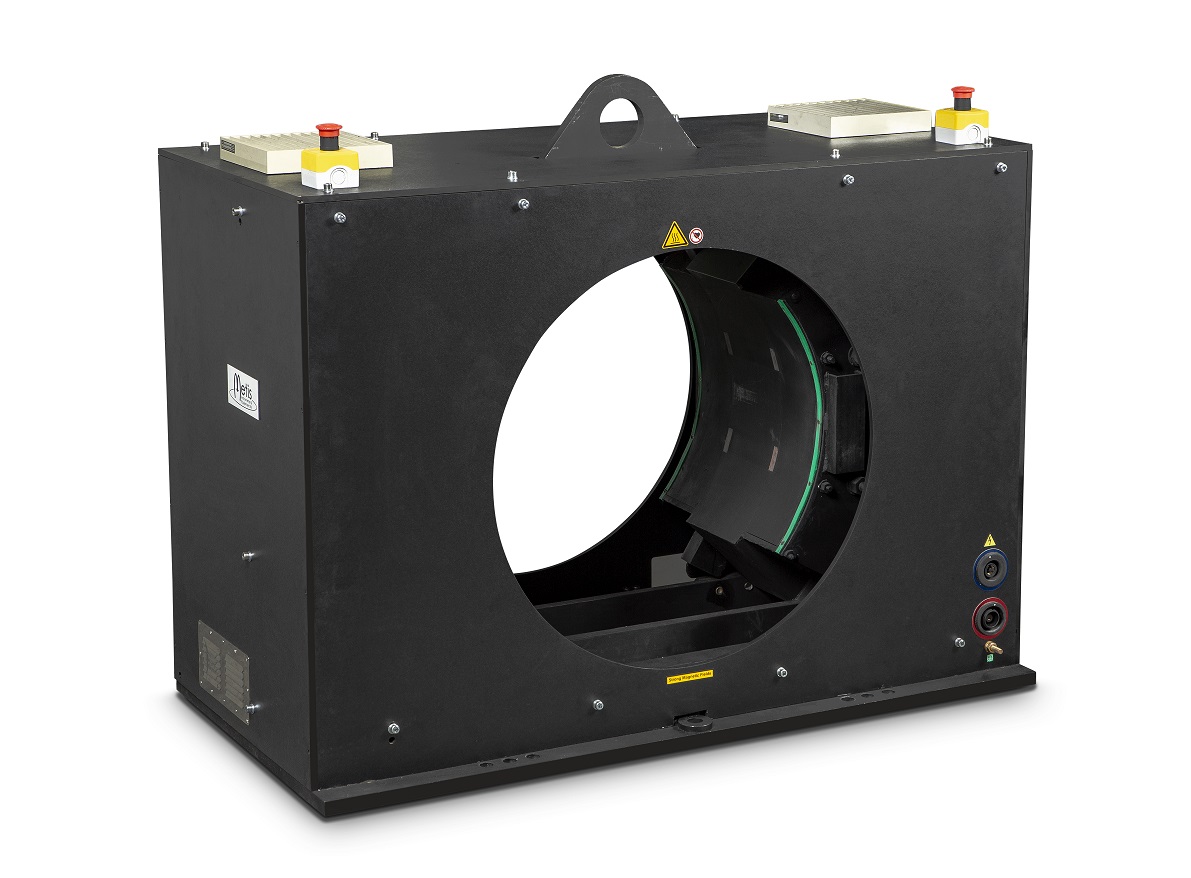

Magnetization fixtures for advanced magnetizing applications.Our magnetizing fixtures are optimized for each individual application using finite element calculation and analytical methods. The design is based on a thorough evaluation of the material properties, the required field strength and the product geometry. By optimizing the internal stress distribution, the fixture lifetime vs. performance ratio is greatly enhanced.

Advantages of magnetizing:

- Economical solution, through Metis’ design of energy efficient magnetizing coils

- Avoid storage of large amounts of pre-magnetized material and components

- Avoid difficult handling of pre-magnetized magnets because the strong magnetic forces can cause danger to operator and the strong magnetic forces can require expensive positioning tooling

- Faster production due to a hassle-free mounting of the magnets,

- The magnetizing time is less than 1 to 2 hours depending on rotor length and due to a scalable production process enabling larger production volumes

- Flexible production solution allowing different geometries to be magnetized with moderate extra investements

- Improved product quality through better tolerances on magnet positioning resulting in better product characteristics, because of the ability to influence neutral zone & skewness and due to the conditioning of magnets for realizing a constant product performance

- On-line quality control of product performance related parameters.

For instance, the minimization of neutral zones or the shape (e.g. sinusoidal or square wave) of the profile can have a substantial impact on the performance of the end-product. Our magnetizing fixtures are optimized for each individual application using finite element calculation and analytical methods.

The design is based on a thorough evaluation of the material properties, the required field strength and the product geometry. By optimizing the internal stress distribution, the fixture lifetime vs. performance ratio is greatly enhanced.

The end user’s production requirements are taken into account such as for instance:

- forced air or liquid cooling

- remote control

- additional diagnostics

- pulse repetition rate

- integration into an automated production line

- ...

All fixtures are protected against overheating through a temperature sensor.

With the realization of high rep rates through internal liquid cooling we can generate a higher productivity.

Prior to designing a magnetizing fixture, Metis makes and in-depth analysis of the magnetization profile that is most suited for the application at hand. For instance, the minimization of neutral zones or the shape (e.g. sinusoidal or square wave) of the profile can have a substantial impact on the performance of the end-product. Metis’ magnetizing fixtures are being used in various application areas: permanent magnet motors, actuators, clutches, holding systems, loudspeakers and metal waste separation.

Need more information about our magnetization fixtures?

Don't hesitate to contact us.